13

Sep

Sep

ROTEX®ZWN

Product characteristics

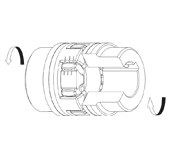

Description of coupling

ROTEX® - couplings are characterized by small dimensions, low weight and low mass moments of inertia yet transmit high torques. Running quality and service life of the coupling are improved by accurate all-over machining.

Their application is ideal for transmitting torque while damping torsional vibrations and absorbing shocks produced by the uneven operation of certain prime movers.

|

General description

ROTEX® - couplings are torsionally flexible and designed for; positive torque transmission. They are fail-safe. Operational vibrations; and shocks are efficiently dampened and reduced. The two congruent; coupling halves with concave claws on the inside are periphally offset; in relation to one another by half a pitch.

In addition, they are designed in such a way as to enable an involute spider to be located between them.

The teeth of the spider are crowned to avoid edge pressure if the shafts are misaligned.

ROTEX® couplings are capable of compensating for axial, radial and angular displacements of the shafts to be connected.

Performance

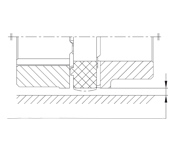

In contrast to other flexible couplings, the intermediate members; of which are subject to bending stress and are therefore prone to; earlier wear, the flexible teeth of ROTEX couplings are subject to; pressure only. This gives the additional advantage of the individual; teeth being able to accept considerably higher loads.The elastomer parts; show deformation with load and excessive speeds. Sufficient space for; expansion should be ensured (see drawing – deformation with load).

The maximum torsion angle with ROTEX couplings of any size amounts to 5°. They can be fitted both horizontally and vertically.

Explosion-proof use

In contrast to other flexible couplings, the intermediate members; of which are subject to bending stress and are therefore prone to; earlier wear, the flexible teeth of ROTEX couplings are subject to; pressure only. This gives the additional advantage of the individual; teeth being able to accept considerably higher loads.The elastomer parts; show deformation with load and excessive speeds. Sufficient space for; expansion should be ensured (see drawing – deformation with load).

The maximum torsion angle with ROTEX couplings of any size amounts to 5°. They can be fitted both horizontally and vertically.

Explosion-proof use

ROTEX® couplings are suitable for power transmission in drives in; hazardous areas. The couplings are certified and confirmed according to; EC standard 94/9/EC (ATEX 95) as units of category 2G/2D and thus; suitable for the use in hazardous areas of zone 1, 2, 21 and 22. Please; read through our information included in the respective Type Examination; Certificate and the operating and mounting instructions.