13

Sep

Sep

ROTEX®GS COMPACT

Product characteristics

|

General description

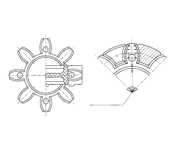

| The straight toothing of the spider mounted under prestress results in a smaller surface pressure and consequently higher stiffness of the coupling system. The flexible teeth compensate for misalignment but are supported radially in the inside diameter by a central web. This avoids too high internal or external deformation by high acceleration or high speeds. This is vital for a smooth operation and long service life of the coupling. |

Performance

The hub claws and the nylon teeth are chamfered to allow for a "blind assembly". The pegs arranged reciprocally on the spider prevent the spider from touching the hub over the entire surface. Observing the distance dimension E ensures the ability of the coupling to compensate for displacements. The plug-in force varies depending on the Shore hardness and prestress of the spider (see comments in the mounting instructions KTR-N 45510).

By observing the gap dimension "s" the electrical isolation is ensured, as well as a high service life of the coupling. This fact is gaining more and more importance, due to the increasing precision of shaft encoders and the existing demand for electro-magnetic compatibility.

Explosion-proof use

ROTEX® GS couplings are suitable for power transmission in drives in hazardous areas. The couplings are certified and confirmed according to EC standard 94/9/EC (ATEX 95) as units of category 2G/2D and thus suitable for the use in hazardous areas of zone 1, 2, 21 and 22. Please read through our information included in the respective Type Examination Certificate and the operating and mounting instructions

Spiders

The elastic spiders of the GS line are available in three different kinds of Shore hardness, identified by colour, the material being soft to hard. Due to these four spiders with different kinds of Shore hardness it is easily possible to adjust the ROTEX® GS regarding the torsional stiffness and the vibration behaviour to the individual conditions of an application.