Sep

MINEX® SIZES SA 110/16 TO SE 200/30 WITH STATIONARY CAN

|

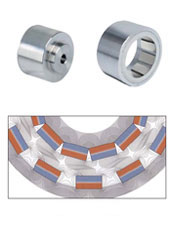

The MINEX®-S is a permanent-magnetic synchronous coupling that transmits torque through magnetic forces between the internal and the external rotor.

It ensures a hermetic separation of the drive and the driven side in its main function as sealing element in pumps and agitators. For critical media like aggressive acids etc. it serves as a reliable seal and prevents serious leakages occuring.

On request KTR can manufacture special customer-specific types of the MINEX®-S in connection with KTR hydraulic components. Thus existing pumps with a conventional shaft seal can be easily retrofitted with the MINEX®-S.

In their non-operative states the north and south poles of the rotors are opposite to each other and the magnetic field is completely symmetric. It is only when the rotors are twisted that the magnetic field lines are moved, hence the torque is transmitted through the air gap. Then there is a synchronous operation under a constant torsion angle.

If the maximum coupling torque and the maximum torsion angle are exceeded, the power transmission is interrupted. Thus the MINEX®-S offers an overload protection function of the drive train. After removing the cause of the overload (e. g. damage to the bearing, blocking of the internal rotor) both rotors can be synchronised again and operation is resumed.

Sealing function

The main component of the MINEX®-S is the containment shroud that is fixed to the driven-sided power unit and separates internal and external rotor from each other. It ensures a low-vibration torque transmission working without mechanical connection and guarantees a completely leak-proof separation of product and atmosphere. The sealing is achieved with a flat seal or an o-ring, thus eliminating the need to dynamically load the sealing elements.

The containment shroud and internal rotor are generally made from stainless steel 1.4571 or Hastelloy. The magnets of the internal rotor are encapsulated to make them impervious to fluids and thus protected against external influences.

Since the containment shroud is a stationary component with a rotating magnetic field, it causes losses of eddy current. In order to keep these low, the containment shroud is also available in Hastelloy from size 75 upwards ensuring a higher electrical resistance than stainless steel. If eddy current losses can definitely be excluded, alternative materials like PEEK or ceramics may be chose.