12

Sep

Sep

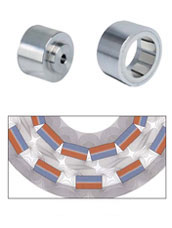

MINEX®-S SIZES SA 75/10 TO SB 250/38

Product characteristics

|

Function

| The coupling consists of an external and an internal rotor. Theexternal rotor has high-quality, permanent magnets of changing polarityon the inner side and the internal rotor has them on the outside. Theexternal rotor is normally fixed on the drive side and the magnets areglued in the keyways. The magnets of the driven-sided internal rotor arecylindrically ground to ensure a minimal air gap and encapsulatedthrough a magnetic cover that is impervious to fluids. In their non-operative states the north and south poles of the rotorsare opposite to each other and the magnetic field is completelysymmetric. It is only when the rotors are twisted that the magneticfield lines are moved, hence the torque is transmitted through the airgap. Then there is a synchronous operation under a constant torsionangle. If the maximum coupling torque and the maximum torsion angle areexceeded, the power transmission is interrupted. Thus the MINEX®-Soffers an overload protection function of the drive train. Afterremoving the cause of the overload (e. g. damage to the bearing,blocking of the internal rotor) both rotors can be synchronised againand operation is resumed. |

Sealing function

| The main component of the MINEX®-S is the containment shroud thatis fixed to the driven-sided power unit and separates internal andexternal rotor from each other. It ensures a low-vibration torquetransmission working without mechanical connection and guarantees acompletely leak-proof separation of product and atmosphere. The sealingis achieved with a flat seal or an o-ring, thus eliminating the need todynamically load the sealing elements. The containment shroud and internal rotor are generally made fromstainless steel 1.4571 or Hastelloy. The magnets of the internal rotorare encapsulated to make them impervious to fluids and thus protectedagainst external influences. Since the containment shroud is a stationary component with arotating magnetic field, it causes losses of eddy current. In order tokeep these low, the containment shroud is also available in Hastelloyfrom size 75 upwards ensuring a higher electrical resistance thanstainless steel. If eddy current losses can definitely be excluded,alternative materials like PEEK or ceramics may be chose. |

Explosion-proof use

MINEX®-S couplings are suitable for the power transmission indrives that are used in hazardous areas. As a component of the deviceclass II the couplings are assessed and confirmed for the use inexplosive areas of category 2G according to the EU standards 94/9/EC(ATEX 95).

Please see our website www.ktr.com for advice, copies of certification and operating/mounting instructions.